Our Units

Ordnance Factory Medak

The Ordnance Factory Medak had come live with the foundation stone being laid by the then Prime Minister of India Smt Indira Gandhi on 19, July, 1984 with an aim to manufacture SARATH - the chariot to victory for Indian Army.

SARATH is one of the best Infantry Combat Vehicles in the world with the modern weapon systems. India joined a Select Club of countries producing State of the Art Infantry Combat Vehicles with the creation of Ordnance Factory, Medak. Within a span of three years of foundation, chariots to victory started rolling out of Medak. The main objectives of OFMK stand tall for:

- To manufacture and supply State of art Armoured Vehicles and Defence Products to meet requirement of Armed and Paramilitary forces.

- Self-reliance in Armoured Vehicles.

- To capture the International Market of Armoured Vehicles.

- To maintain the world class competency in production of Armoured Vehicles.

1. Product Profile

a) BMP-II and BMP-IIK:were developed through TOT from Russia and indigenized to an extent of 98.5 % over a period of time.

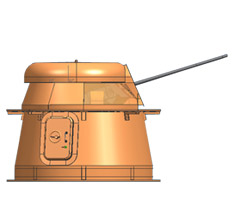

BMP-II known as APC ‘Sarath’ - is fully tracked, highly mobile amphibian ICV with 30mm fully stabilized automatic cannon, 7.62 mm PKT Machine Gun and 4 kms range anti-tank wire guided ‘Konkurs’ Missile housing 7 troopers and 3 crews. Its crew is protected from NBC attacks.It is also equipped with Night Vision Device & Smoke Grenade Launchers system.

It is powered by a 300 HP Engine, meets all tactical requirement of mobility in a battle field, travels at an incredible speed of 65 kms. It has a 30-mm cannon and second generation Anti-Tank Guided Missile (ATGM)- Konkurs missile. The 30 mm gun can fire @ 550 rounds per minute, with a range of 2000 M for ‘piercing armour’ and 4000 M for ‘high explosive’ projectiles. The Gun which is stabilized, maintains the orientation of the barrel when the vehicle is mobile.

OFMK manufactured and supplied BMP Variants in association with CVRDE, VRDE & DL, Jodhpur

- Carrier Motor Tracked- (CMT)

- Armoured Ambulance Tracked (AAT)

- Armoured Reconnaissance Vehicle(AERV)

- Nuclear Biological & Chemical Recce Vehicle

- Armoured Amphibious Dozer(AAD)

- CCPT

BMP Variants developed as a part of Integrated Guided Missile Development Project (IGMDP) are:

- TRISHUL

- NAMICA

- AKASH

2. State Of Art Technologies :

OFPM has a wide range of modern 5 Axis and 3 Axis laser cutting machines, Plasma Cutting Machines, 4000T and 1600T Cold & Hot Press and wide variety of sophisticated CNC machines for Machining, Thermo Pressing, Welding, and Surface Treatment.

In 2006, CNC Double Column Plano Milling Machine and CNC Vertical Turning, Boring and Milling Machine were added to the plant and machineries of OFMK. The Factory has its own CNC Lab and CAD/CAM Centre.

The State of Art Foundry is capable of producing intricate and complex Aluminum & precision steel castings. OFPM also has a Metallurgical Laboratory accredited by NABL.

Aluminium Engine Castings of Sarath& T-72 Tank were made through

- Liquid Metal Die Forging

- Gravity Die Casting

- Low Pressure Die Casting

- Sand Castings

- Core Making Facility

and Steel Investment Castings weighing 10 gm to 7 kg are made at Foundry.

The factory is ISO 9001:2000 certified having focus on improvement in quality of products supplied and external/internal customer complaints received. It is certified for ISO 9001: 2000 Quality Management system EMS IS/ISO: 14001-1996 by BIS.

3. OFMK Vision:

Production of State of the Art Battle Field Equipments.

4. OFMK Mission:

- To equip our Armed Forces with modern “Defence and Battle Field Equipments”

- To continuously modernize our production facilities.

- To train and motivate personnel.

- To equip ourselves with technologies through acquisition, synergy and in-house R &D.

- To continuously improve quality.

- To improve operational efficiency and communications by extensive use of information technology.

- To achieve highest level of customer satisfaction.

- To increase customer base in defence, non-defence and export markets and establish global presence.

5. R&D Strategy

The Strategy is based on threefanged approach: In-House R&D, Co-Development and Co-Production. Serious efforts have been made to develop FICV through forged technological alliances with IITs, IISc and Industry partners. The Academic engagement has been a top priority model chosen by OFMK to nurture new Military technologies. Technology partnered with DRDO labs, OFMK is all set to develop Future Ready Military Vehicles.

6. Mile Stones Of OFMK

- In 2006, a mega plantation project was launched in 200 acres of factory by Hon’ble Chief Minister of Andhra Pradeshand Total 2.64 Lakh plants have been planted in the estate to maintain eco-friendly environment.

- O.F Medak won the “Golden Peacock National Quality Award” for the year 2007, “Golden Peacock HR Excellence Award” for the year 2015 & “Golden Peacock Innovative Product / Service Award” for the year 2016.

- OFMK bagged Hon’ble Raksha Mantri Award for Excellence for the year 2014-15 & 2015-16.

- The factory is also certified for ISO 14001 for Environmental Management System. OFMK has bagged “Golden Peacock Environment Award for 2017”

- O.F Medak has issued 2314 Nos of BMP-II/IIK, 207 Nos. of Armoured Ambulance Tracked Vehicles and 219 No of CMTs to Army. Around 30 No of BMP variants to other Agencies.

- Today, the factory stands for excellence in technology and management with a clean and green township for 2693 families with all the facilities including modern clubs, swimming pool, stadium equipped with all the facilities, public schools including one Kendriya Vidyalaya, 50 bedded hospitals with visiting specialists and commercial facilities.

- OFMK has extended the support to Ministry of HRD, for setting up of Indian Institute of Technology Hyderabad in Ordnance Factory Estate.

- Women Welfare Association at Ordnance Factory Medak is also rendering valuable services. The nursery school, being run by WWA is also contributing to the educational, recreational welfare activities in the township.

- The Productivity and overall earnings of its employees has been on the rise and there has been an overall improvement in the living standards of its employees.

In nutshell, Ordnance Factory Medak is a big industrial complex pulsating with life and has tremendous potential for future growth.

- May 2017 : 16MW Solar Power Plant inaugurated by Hon’ble Raksha Mantri Shri Arun Jaitley through video link.

- Aug 2017 : Bar Coded BMP-II was handed over to DGMF in the presence of Hon’ble Raksha Mantri Shri Arun Jaitley on 27.08.2017

- July 2019 : India stood first during International exercises of BMP Veh conducted at Jaisalmer – Scout Masters Competitions

- April 2020 : 2nd Overhauling of BMP Vehicles started for the first time at OFMK.

- Aug 2020 : Launching of NAMICA Vehicle by Hon’ble Raksha Mantri Shri Rajnath Singh through VC

- July 2021 : 1 Lakh Avenue Plantation programme launched

Preamble

The first chariot of Ordnance Factory Medak rolled out in the year 1987. In a record time OFMK produced one of the best Infantry Combat Vehicles in the world known as SARATH for the Indian Army. OFMK has mastered the TOT for BMP-II/IIK and manufactured the vehicles with 98.5% indigenisation. OFMK, in collaboration with DRDO, has developed AAT, CMT, AERV and NBCRV to meet the diverse needs of Indian Army.OFMK, through indigenous R&D efforts, has developed Bullet Proof Vehicles and Mine Protection Vehicles to meet the growing needs of MHA and Indian Army. OFMK forayed into CIVIL Trade and Export market as well. OFMK is accredited with IS/ISO 9001:2015(QMS), IS/ISO 14001:2015(EMS) certification and also having accredited Metallurgical Laboratory under NABL ISO/IEC 17025:2005.

Products

Capabilities

OFMK is now producing Bullet Proof Vehicles and poised for production of hulls and turrets for Main Battle Tank(Arjun)and Armour Amphibious Dozar, Rocket Launchers(Pinaka) etc. The diversified product mix in special vehicles and Naval Products is the result of indigenous R & D efforts fortified by in-house CAD / CAM centre at Ordnance Factory, Medak. This has greatly reinforced the Security Forces and also improved the economy of our factory. We have successfully made forays in Civil Trade and Export Market as well. Our business share to the Ministry of Home Affairs and Other Defence Departments has steadily gone up. We have a wide range of modern state-of-art facilities like, Investment Steel Casting and Aluminium Foundry, CNC oriented Light Machining, Heavy Machining and Assembly lines. We are modern Hi-Tech Engineering factory with more than 2000 Nos. of machines covering a wide variety of sophisticated Technologies. viz, 5 and 3 axis CNC Machines, Thermo Pressing Technology, Foam Filling Technology, Welding Technology and Surface Treatment Technology. We are also equipped with 5 axis and 3 axis laser-cutting machines and the Foundry is capable of producing Intricate Aluminium and Precision Steel Castings.

The core competencies of AVNLIOLML includes:- 1) Corporate Communicate, & 2) Marketing including Export

RTI Officers

Shri/Smt K.Vijaya Dat

First Appellate Authority & Transparency Officer

General Manager/HR & Finance

(M) 9445491150, (O) 040-23283209

Email: kvdat[at]ord[dot]gov[dot]in

Shri K. Chandra Mohan

Public Information Officer(PIO) & Grievance Officer

Works Manager

(M) 9831371180, (O)040-23283224

Email: kcmohan[at]ord[dot]gov[dot]in

Smt G.Sujatha

Asst.Public Information Officer(AIPO)

Works Manager

(M) 9848563638, (O) 040-23283257

FAX-08455-239074

Email: sujathag[at]avnl[dot]co[dot]in

Contact Details

Shri Shiva Shankar Prasad, IOFS

Chief General Manager

Ordnance Factory Medak

An Unit of AVNL

Yeddumailaram (PO), Kandi (Mdl)

Sangareddy (Dt)

Telangana - 502205

Ph: 040-23283001 Fax: 040-23292950

Email: gm[dot]ofnk[at]ord[dot]gov[dot]in

Shri. Atul Kumar Bapat

General Manager

Ordnance Factory Medak

An Unit of AVNL

Yeddumailaram (PO), Kandi (Mdl)

Sangareddy (Dt)

Telangana - 502205

Ph: 040-23283801 Fax: 040-23292950

Email: ofpm[dot]ofb[at]nic[dot]in

Notification

REMITTANCE OF FEE : Application fee of Rs. 10/- by way of cash against proper receipt or by Demand Draft / Bankers Cheque / IPO drawn in favour of GMs Public Fund Account, Ordnance Factory, Yeddumailaram payable at SBH , Yeddumailram Br Code 20537